The 20 feet (20') and 40 feet (40') containers are very popular in ocean freight. The 8.5 feet (8.5') high container--- 8 feet 6 inches (8' 6") high container--- is often referred to as standard container.

The demand for the high cube container---hicube---is increasing. The popular high cube container has a normal height of 9.5 feet (9.5' or 9' 6"). There are half height containers (4.25' or 4' 3"

high) designed for heavy loads such as steel rods and ingots, which

absorb the weight limit in half the normal space. The most widely used type of container is the general purpose (dry cargo) container having a nominal length and height of 20' x 8.5' , 40' x 8.5' , and 40' x 9.5' .

Referring to the Dimension of General Purpose Containers below, the dimensions shown in the table are not fixed, that is, the external and internal dimensions may vary among containers of the same length and height.

Dimension of General Purpose Containers

| CONTAINER | Capacity | Recommended Load Volume | |||||

| Nominal Dimension | Length | Width | Height | Cubic Feet | Cubic Meter | Cubic Feet | Cubic Meter |

| External | 20' | 8' | 8' 6" | ||||

| 6.096 m | 2.438 m | 2.591 m | |||||

| Internal | 19' 4.25" | 7' 10" | |||||

| 5.899 m | 2.353 m | ||||||

| External | 40' | 8' | 8' 6" | ||||

| 12.192 m | 2.438 m | 2.591 m | |||||

| Internal | 39' 5.375" | 7' 8.625" | 7' 10" | 2385 cft | 2050 cft | ||

| 12.024 m | 2.353 m | 2.388 m | 67.535 cbm | 58 cbm | |||

| External | 8' | 9' 6" | |||||

| 12.192 m | 2.438 m | 2.896 m | |||||

| Internal | 39' 5.375" | 7' 8.625" | 8' 10" | 2690 cft | 2350 cft | ||

| 12.024 m | 2.353 m | 2.692 m | 76.172 cbm | 66 cbm | |||

| NOTE: | Containers with the same external length may not have exactly the same internal length and width. |

| The Recommended Load Volume (RLV) refers to the suggested maximum cube to use in calculating a full container load. The RLV can be about 10-15% less than the container capacity, depending on the export pack dimensions. |

Rear view of 20' x 8.5' container | CAUTION:

Miscalculated capacity may result in a large empty and unusable space or a shortage in space. For example (see 20' x 8.5'

container diagram on the left), the master cartons have a uniform

height of 20 inches, and the length and width are greater than the

height. If 1170 cubic feet is used to calculate a 20' full container

load, most likely some cartons will not fit despite the empty space of

about 170 cubic feet. You cannot stuff the remaining cartons into the

remaining 14" high empty space.

|

Tare weight or tare is the mass (or weight) of empty container, including all fittings and appliances used in a particular type of container in its normal operating condition.

The tare mass of containers may vary due to the different

construction techniques and materials used in the container. A 20' x

8.5' dry cargo container may weigh 1,800 kgs. to 2,400 kgs., a 40' x 8.5' may weigh 2,800 kgs. to 4,000 kgs, and a 40' x 9.5' may weigh 3,900 kgs. to 4,200 kgs.

Some dry cargo containers may fall outside the indicated weight range.

The reefer weighs more than a dry cargo container of the same size.

Rating

Rating is the maximum gross mass (or weight), that is, the

maximum permissible weight of a container plus its contents. The rating

of a 20' dry cargo container is 24,000 kgs. (52,900 lbs.), and a 40', including the high cube container, is 30,480 kgs. (67,200 lbs.).

Payload

Payload is the maximum permitted mass (or weight) of payload, including the dunnage and cargo securement arrangements that are not associated with the container in its normal operating condition. Therefore, Payload = Rating - Tare Mass.

If the tare mass of a 20' dry cargo container is 2,400 kgs. and a 40' is 3,900 kgs., the payload of 20' is 21,600 kgs. (i.e., 24,000 kgs. minus 2,400 kgs.) and 40' is 26,580 kgs. (i.e., 30,480 kgs. minus 3,900 kgs.). However, the exporter may be prohibited to have that much payload in areas where there are legal limitations to the overall load of a vehicle.

In exporting, it is common to encounter a payload of 17,500 kgs. or less in the 20' container, and 24,000 kgs. or less in the 40' container.

Payload is the maximum permitted mass (or weight) of payload, including the dunnage and cargo securement arrangements that are not associated with the container in its normal operating condition. Therefore, Payload = Rating - Tare Mass.

If the tare mass of a 20' dry cargo container is 2,400 kgs. and a 40' is 3,900 kgs., the payload of 20' is 21,600 kgs. (i.e., 24,000 kgs. minus 2,400 kgs.) and 40' is 26,580 kgs. (i.e., 30,480 kgs. minus 3,900 kgs.). However, the exporter may be prohibited to have that much payload in areas where there are legal limitations to the overall load of a vehicle.

In exporting, it is common to encounter a payload of 17,500 kgs. or less in the 20' container, and 24,000 kgs. or less in the 40' container.

The Marking and Identification of Containers

The rating, tare mass and payload of a container is marked on its wall, usually on the end (rear) door in the case of an end-loading dry cargo container.

The rating, tare mass and payload of a container is marked on its wall, usually on the end (rear) door in the case of an end-loading dry cargo container.

Each container has an identification code or container number - a combination of the 4-letter characters that identify the owner (the operator of container) and the 7-numeric characters that identify the container. The container number can be found on the outer and inner side walls.

The container number is entered on the bill of lading to facilitate the identification and tracking of the container and the cargo.

Container Types

Bulk (or bulk cargo) containers have three loading hatches in the roof,

each of a diameter of approx. 455 mm (1 3/4'). The distance between the

hatches (center to center) is 1.83 m (6'). On the door side, there are

two discharge hatches, which are sometimes equipped with short discharge

tubes for guiding the bulk cargo. Alternatively, two unloading hatches

may be mounted in the doorways, for emptying the containers.

Such containers may also be used for general cargo. Lashing rings are

mounted in the top side rails for securing the cargo. Some bulk

containers are equipped with forklift pockets, which allow handling by

forklift trucks.

Figures

Usage

Bulk containers are used in particular for transporting bulk cargo, such

as grain, feedstuffs, spices. However, they may also be used for

transporting general cargo.

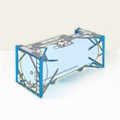

20" Tank

|

INSIDE LENGTH | 6.058 m |

| INSIDE WIDTH | 2.438 m | |

| INSIDE HEIGHT | 2.4380 m |

Tank containers must be at least 80% full, to prevent dangerous surging of the liquids in transit. On the other hand, they must not as a rule be over 95% full, or there will not be sufficient ullage space for thermal expansion. The extent of thermal expansion may be calculated for each cargo on the basis of the following formula:

- ΔV = Va · γ · ΔT

- Ve = Va (1 + γ · ΔT)

Va : volume at initial temperature a

Ve : final volume at temperature e

γ : coefficient of cubic (thermal) expansion

ΔT : temperature difference in degrees kelvin

Tank containers intended for transporting foodstuffs must be labeled "Potable Liquids only".

Some hazardous materials must be transported in tank containers with no in- or outlet openings below the surface of the liquid.

Tank containers are generally designed for an operating pressure of up

to 3 bar (above atmospheric). The test pressure used is 4.5 bar (above

atmospheric).

If the cargo requires temperature-controlled transport, tank containers can be equipped with insulation or heating. The temperature of the cargo may be precisely controlled using temperature sensors.

If the cargo requires temperature-controlled transport, tank containers can be equipped with insulation or heating. The temperature of the cargo may be precisely controlled using temperature sensors.

Figures

Usage

Tank containers are used for liquid cargoes, such as:- Foodstuffs: fruit juices, spirits, sweet oils

- Chemicals: hazardous materials, such as fuels, toxic substances, corrosion protection agents

|

INSIDE LENGTH | 5.8950 m |

| INSIDE WIDTH | 2.350 m | |

| INSIDE HEIGHT | 2.392 m |

Standard containers are also known as general purpose containers.

They are closed containers, i.e. they are closed on all sides. A

distinction may be drawn between the following types of standard

container:

- Standard containers with doors at one or both end(s)

- Standard containers with doors at one or both end(s) and doors over the entire length of one or both sides

- Standard containers with doors at one or both end(s) and doors on one or both sides

In addition, the various types of standard container also differ in

dimensions and weight, resulting in a wide range of standard containers.

Standard containers are mainly used as 20' and 40' containers.

Containers with smaller dimensions are very seldom used. Indeed, the

trend is towards even longer dimensions, e.g. 45'.

Figures

Usage

Standard containers are used for all types general cargo (dry cargo).20" Open Top

|

INSIDE LENGTH | 5.8880 m |

| INSIDE WIDTH | 2.345 m | |

| INSIDE HEIGHT | 2.315 m |

The walls of open-top containers are generally made of corrugated steel. The floor is made of wood.

It has the following typical distinguishing structural features. The

roof consists of removable bows and a removable tarpaulin. The door

header may be swivelled out.

These two structural features greatly simplify the process of packing and unpacking the container. In particular, it is very easy to pack and unpack the container from above or through the doors by crane or crab when the roof is open and the door header is swivelled out.

It should be noted, however, that the purpose of the roof bows of an open-top container is not solely to support the tarpaulin but also to contribute to container stability. Flatracks are therefore more suitable for overheight cargoes.

These two structural features greatly simplify the process of packing and unpacking the container. In particular, it is very easy to pack and unpack the container from above or through the doors by crane or crab when the roof is open and the door header is swivelled out.

It should be noted, however, that the purpose of the roof bows of an open-top container is not solely to support the tarpaulin but also to contribute to container stability. Flatracks are therefore more suitable for overheight cargoes.

Lashing rings, to which the cargo may be secured, are installed in the upper and lower side rails and the corner posts. The lashing rings may take loads of up to 1,000 kg.

Usual open-top container dimensions are 20' and 40'.

Figures

Usage

Open-top containers are used for all types of general cargo (dry cargo). Their principal uses are as follows:- packing and unpacking from above or through the doors by crane or crab

- tall cargo

|

INSIDE LENGTH | 5.698 m |

| INSIDE WIDTH | 2.230 m | |

| INSIDE HEIGHT | 2.2550 m |

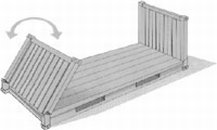

Flatracks consist of a floor structure with a high loading capacity

composed of a steel frame and a softwood floor and two end walls, which

may either be fixed or collapsible. The end walls are stable enough to

allow cargo securing means to be attached and several flatracks to be

stacked on top of one another. Flatracks are available in 20' and 40'

sizes.

A number of lashing rings, to which the cargo may be secured, are installed in the side rails, the corner posts and the floor. The lashing rings may take loads of up to 2000 kg in the case of 20' flatracks or up to 4000 kg in the case of 40' flatracks. Some types of 20' flatracks have forklift pockets. 40' flatracks have gooseneck tunnels at each end. In addition, they are sometimes equipped with lashing winches with 2 metric ton lashing belts. For transport of certain cargoes, flatracks may be provided with stanchions.

A number of lashing rings, to which the cargo may be secured, are installed in the side rails, the corner posts and the floor. The lashing rings may take loads of up to 2000 kg in the case of 20' flatracks or up to 4000 kg in the case of 40' flatracks. Some types of 20' flatracks have forklift pockets. 40' flatracks have gooseneck tunnels at each end. In addition, they are sometimes equipped with lashing winches with 2 metric ton lashing belts. For transport of certain cargoes, flatracks may be provided with stanchions.

Figures

Usage

Flatracks are mainly used to transport heavy-lifts and overheight or overwidth cargoes.20" FLATRACK COLLAPSIBLE

|

INSIDE LENGTH | 5.675 m |

| INSIDE WIDTH | 2.2130 m | |

| INSIDE HEIGHT | 2.270 m |

Flatracks consist of a floor structure with a high loading capacity

composed of a steel frame and a softwood floor and two end walls, which

may either be fixed or collapsible. The end walls are stable enough to

allow cargo securing means to be attached and several flatracks to be

stacked on top of one another. Flatracks are available in 20' and 40'

sizes.

A number of lashing rings, to which the cargo may be secured, are installed in the side rails, the corner posts and the floor. The lashing rings may take loads of up to 2000 kg in the case of 20' flatracks or up to 4000 kg in the case of 40' flatracks. Some types of 20' flatracks have forklift pockets. 40' flatracks have gooseneck tunnels at each end. In addition, they are sometimes equipped with lashing winches with 2 metric ton lashing belts. For transport of certain cargoes, flatracks may be provided with stanchions.

A number of lashing rings, to which the cargo may be secured, are installed in the side rails, the corner posts and the floor. The lashing rings may take loads of up to 2000 kg in the case of 20' flatracks or up to 4000 kg in the case of 40' flatracks. Some types of 20' flatracks have forklift pockets. 40' flatracks have gooseneck tunnels at each end. In addition, they are sometimes equipped with lashing winches with 2 metric ton lashing belts. For transport of certain cargoes, flatracks may be provided with stanchions.

Figures

Usage

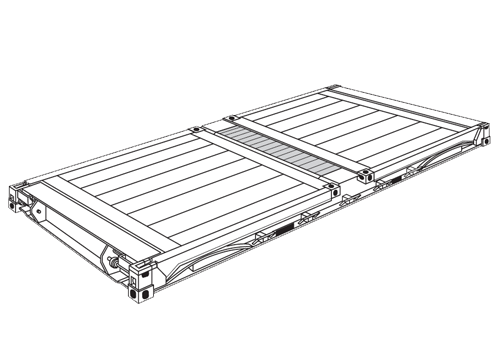

Flatracks are mainly used to transport heavy-lifts and overheight or overwidth cargoes.20" PLATFORM

|

INSIDE LENGTH | 6.0580 m |

| INSIDE WIDTH | 2.438 m | |

| INSIDE HEIGHT | 0.370 m |

Platforms consist solely of a floor structure with extremely high loading capacity; they have no side or end walls. This high loading capacity makes it possible to concentrate heavy weights on small areas. A platform consists of a steel frame and a wooden floor structure.

Platforms are available in 20' and 40' sizes. 40' platforms have a gooseneck tunnel at each end. Lashing rings, to which the cargo may be secured, are installed in the side rails. The lashing rings may take loads of up to 3.000 kg.

Figures

Usage

Platforms are used principally for oversized and very heavy cargoes.20" Refrigerated

|

INSIDE LENGTH | 5.724 m |

| INSIDE WIDTH | 2.286 m | |

| INSIDE HEIGHT | 2.0140 m |

The refrigeration unit is arranged in such a way that the external

dimensions of the container meet ISO standards and thus fit into the

container ship cell guides, for example. The presence of an integral

refrigeration unit entails a loss of internal volume and payload.

When being transported by ship, integral units have to be connected to

the on-board power supply system. The number of refrigerated containers

which may be connected depends on the capacity of the ship's power

supply system. If the aforesaid capacity is too low for the refrigerated

containers to be transported, "power packs" may be used, which are

equipped with relatively large diesel generators and satisfy ISO

requirements with regard to the dimensions of a 20' container. When at

the terminal, the containers are connected to the terminal's power

supply system. For transport by road and rail, most integral unit

refrigeration units are operated by a generator set (genset). This may

either be a component of the refrigeration unit or connected to the

refrigeration unit.

When being transported by ship, integral units have to be connected to

the on-board power supply system. The number of refrigerated containers

which may be connected depends on the capacity of the ship's power

supply system. If the aforesaid capacity is too low for the refrigerated

containers to be transported, "power packs" may be used, which are

equipped with relatively large diesel generators and satisfy ISO

requirements with regard to the dimensions of a 20' container. When at

the terminal, the containers are connected to the terminal's power

supply system. For transport by road and rail, most integral unit

refrigeration units are operated by a generator set (genset). This may

either be a component of the refrigeration unit or connected to the

refrigeration unit.

When being transported by ship, integral units have to be connected to

the on-board power supply system. The number of refrigerated containers

which may be connected depends on the capacity of the ship's power

supply system. If the aforesaid capacity is too low for the refrigerated

containers to be transported, "power packs" may be used, which are

equipped with relatively large diesel generators and satisfy ISO

requirements with regard to the dimensions of a 20' container. When at

the terminal, the containers are connected to the terminal's power

supply system. For transport by road and rail, most integral unit

refrigeration units are operated by a generator set (genset). This may

either be a component of the refrigeration unit or connected to the

refrigeration unit.

When being transported by ship, integral units have to be connected to

the on-board power supply system. The number of refrigerated containers

which may be connected depends on the capacity of the ship's power

supply system. If the aforesaid capacity is too low for the refrigerated

containers to be transported, "power packs" may be used, which are

equipped with relatively large diesel generators and satisfy ISO

requirements with regard to the dimensions of a 20' container. When at

the terminal, the containers are connected to the terminal's power

supply system. For transport by road and rail, most integral unit

refrigeration units are operated by a generator set (genset). This may

either be a component of the refrigeration unit or connected to the

refrigeration unit.

Air flows through the container from bottom to top. In general, the

"warm" air is drawn off from the inside of the container, cooled in the

refrigeration unit and then blown back in the container as cold air.

To ensure adequate circulation of the cold air, the floor is provided

with gratings. Pallets form an additional space between container floor

and cargo, so also forming a satisfactory air flow channel. In addition,

the side walls of the container are "corrugated", which ensures

satisfactory air flow there too.

In the upper area of the container, adequate space (at least 12 cm) must

likewise be provided for air flow. For this purpose, during packing of

the container adequate free space must be left above the cargo. The

maximum load height is marked on the side walls.

In the upper area of the container, adequate space (at least 12 cm) must

likewise be provided for air flow. For this purpose, during packing of

the container adequate free space must be left above the cargo. The

maximum load height is marked on the side walls.To ensure vertical air flow from bottom to top, packaging must also be appropriately designed and the cargo must be sensibly stowed. In addition to temperature regulation, integral units also allow a controlled fresh air exchange, for example for the removal of metabolic products such as CO2 and ethylene in the case of the transport of fruits.

In the refrigeration units, both the supply and return air temperatures are measured and, depending on the operating mode, one of these values is used to control the cold air. Temperature measurement may be performed in various ways. The Partlow recorder generally records return air temperature, since this provides an indication of the state or temperature of the cargo. Data loggers are increasingly used, which detect temperature digitally and indicate it on a display. Once transferred to a PC, the data may then be evaluated. The temperature display is attached to the outside of the refrigeration unit, so that operation of the unit may be checked at any time. Digital or analog recorders may also be positioned directly in the cargo, so as to measure temperatures inside the container. The recorder should be accommodated in such a way that it records the temperatures at risk points in the container (inside the packaging, top layer at door end).

Integral units may be stowed both above and below deck on a ship. Above

deck stowage has the advantage that the heat from return air may be more

readily dissipated. However, the containers are often exposed to strong

solar radiation, leading to increased refrigeration capacity

requirements.

Figures

Usage

Refrigerated containers are used for goods which need to be transported

at a constant temperature above or below freezing point. These goods are

divided into chilled goods and frozen goods, depending on the specified

transport temperature. They principally include fruit, vegetables, meat

and dairy products, such as butter and cheese.

High-cube integral units are used in particular for voluminous and light goods (e.g. fruit, flowers).

Nowadays, goods requiring refrigeration are mostly transported in integral units, which have a markedly higher market share than porthole containers. Chilled meat is sometimes also transported hanging, for which purpose the ceilings of refrigerated containers are equipped with special hook rails.

Nowadays, goods requiring refrigeration are mostly transported in integral units, which have a markedly higher market share than porthole containers. Chilled meat is sometimes also transported hanging, for which purpose the ceilings of refrigerated containers are equipped with special hook rails.

40" Standard

|

INSIDE LENGTH | 12.029 m |

| INSIDE WIDTH | 2.350 m | |

| INSIDE HEIGHT | 2.392 m |

Standard containers are also known as general purpose containers.

They are closed containers, i.e. they are closed on all sides. A

distinction may be drawn between the following types of standard

container:

- Standard containers with doors at one or both end(s)

- Standard containers with doors at one or both end(s) and doors over the entire length of one or both sides

- Standard containers with doors at one or both end(s) and doors on one or both sides

Figures

Usage

Standard containers are used for all types general cargo (dry cargo).40" High-Cube

|

INSIDE LENGTH | 12.024 m |

| INSIDE WIDTH | 2.350 m | |

| INSIDE HEIGHT | 2.697 m |

High-cube containers are similar in structure to standard containers,

but taller. In contrast to standard containers, which have a maximum

height of 2591 mm (8'6"), high-cube containers are 2896 mm, or 9'6",

tall. High-cube containers are for the most part 40' long, but are

sometimes made as 45' containers.

A number of lashing rings, capable of bearing loads of at most 1000 kg, are mounted on the front top end rail and bottom cross member and the corner posts. Many 40' containers have a recess in the floor at the front end which serves to center the containers on so-called gooseneck chassis. These recesses allow the containers to lie lower and therefore to be of taller construction.

A number of lashing rings, capable of bearing loads of at most 1000 kg, are mounted on the front top end rail and bottom cross member and the corner posts. Many 40' containers have a recess in the floor at the front end which serves to center the containers on so-called gooseneck chassis. These recesses allow the containers to lie lower and therefore to be of taller construction.

Figures

Usage

High-cube containers are used for all types general cargo (dry cargo). However, they are particularly suitable for transporting light, voluminous cargoes and overheight cargoes up to a maximum of 2.70 m tall.References Site: export911

hi. just dropped by to say how much i appreciate you taking time to share such wonderful posts.

ReplyDeleteCollapsible Bulk Containers

Very nice blog. Great to know about Container Types in India.

ReplyDeletehi

ReplyDeleteThank you for sharing such a beautiful information. I hope you will continue sharing this type information.

ReplyDeletecontainer storage units for sale Michigan